Using Emulsions to Select by Yield

Background

Evolution in suspension culture proceeds by selecting for those strains that grow most rapidly, quickly depleting the media of nutrients and preventing other strains from competing. In order to select for cells that grow more efficiently (defined as a higher yield of cells generated per unit volume of media) it is necessary to compartmentalize individual cells from a starter culture, allow for growth to stationary phase, and then rupture the individual compartments to create a new pool of cells for another round of growth in compartments. Since slow-growing but efficient cells will have a higher yield, they will be enriched relative to less efficient, even if faster growing, cells after every round. To achieve compartmentalization, we can use oil in water emulsions. Mixing a culture in aqueous media with an oil/surfactant mix under the right conditions produces droplets of media in which cells can grow. These emulsion droplets can then be broken chemically. It is possible using microfluidics to fill every emulsion droplet with a cell; however, this is an expensive set up and is too low-throughput for many experiments. Below is methodology for growing cells in relatively cheap and easy to produce water-in-oil emulsions. Before venturing in to this experiment, consider how many rounds of growth would be required to achieve your anticipated results. Breaking of existing droplets and re-seeding needs to be done every day (although can probably be extended to 48 hours) and the outline below still only allows for growth of hundreds of thousands of cells per day. This protocol requires extensive optimization. The size of the emulsions - such that they are large enough to allow for growth of cells but small enough to compartmentalize as many cells as possible - needs to be determined. Similarly, the number of cells seeding the emulsions needs to be optimized, such that seeding occurs as frequently as possible, but with only single cells per emulsion droplet. These conditions need to be determined by the user and can be done by following the steps for Optimization at the bottom of this page. The following protocol used E.coli, the size of the emulsion droplets created range from 30um - 110um in diameter with a mean of 80um, and approx 7.5% of filled emulsion droplets were seeded with more then one cell.Materials

Chemicals:- HFE (3M cat no. XXXXX)

- Picosurf surfactant, 5% in HFE (Dolomite, cat no. XXXX)

- 2,3-perfluorooctanol (Y, cat no. XXXX)

- Growth media

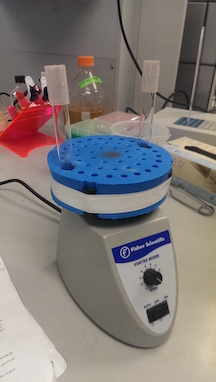

- Vortex genie

- Shaking attachment for vortex genie (cat no. XXXX)

- Glass culture tubes (Fisher 14-961-32).

Protocol, for E.coli.

Do not alter the conditions used to make the emulsions, unless you intentionally plan to change them (see Optimization section below). Emulsion size is sensitive to the type (size, shape) of vessel, the concentration of surfactant, the total volume and the speed/duration of shaking. Day 1:- Grow an overnight culture of strain of interest.

- Precondition strain by making a 1:100 dilution into fresh media and growing overnight.

- Determine OD of overnight culture, ensuring that measurement is taken in the linear range (<0.3).

- From this, calculate the concentration of cells per ml of culture.

- Serially dilute the culture to achieve a final concentration of 2x10^5 cells/ml.

- You will need 300ul of this final, diluted culture per emulsion.

- Perform dilutions in saline; however, the final dilution needs to be into growth media, as it will be used to make emulsions.

- If you are not using E.coli, it is recommended that you optimize the number of cells seeding the emulsion. See the 'Optimization' section below.

- Make up a solution of HFE containing 0.5% Picosurf.

- You will need 700ul of HFE/Picosurf per emulsion.

- In a glass culture tube, pipette 700ul of HFE/picosurf and then gently layer 300ul of diluted culture on top.

- Place the glass tube in the vortex (balanced with an empty tube if necessary) and shake for 5 minutes at full power.

- Leave the emulsion for 10 mins to separate into emulsion and oil phases.

- Pipette away the bottom, oil phase and store in a 15ml Falcon tube. This will be recycled at a later date (see below), thus saving time and money.

- Move the emulsion to a 1.5ml micro centrifuge tube and grow overnight at desired temperature.

- Remove any residual oil phase from the bottom of the centrifuge tube and save in same 15ml Falcon as on Day 3.

- Add 200ul of perfluorooctanol to the emulsion, gently shake, and set aside to break. Occasionally agitate the emulsion/perflourooctanol mix, but you do not need to shake it.

- After 5-10 mins, two phases will appear. Remove the top approximately 200ul phase, containing bacteria. Trash the remaining solution as clearly labelled chemical waste (EHS).

- Determine OD of the collected upper phase, blanked against growth medium, and use this to seed a new emulsion using the methods above.

- Centrifuge the solution for 10 mins at X xg, in order to separate any residual emulsion that may have been transferred.

- Using a syringe, pull off pico surf solution below the emulsion and then filter it through a 0.22 micron filter.

- Use neat in next emulsion.

| I | Attachment | History | Action | Size | Date | Who | Comment |

|---|---|---|---|---|---|---|---|

| |

Emulsion_setup_pic.jpg | r1 | manage | 36.9 K | 2017-03-02 - 23:23 | UnknownUser |

Barrick Lab > ProtocolList > ProcedureSelectingByEfficiency